S-Base™ is a sustainable foundation system, developed especially for temporary buildings such as living quarters, porta cabins, canteens, office buildings, preschools, or school buildings. There is also a special application to be used under steel containers.

Regulations require that such calculations be conducted, even if the building is erected on a construction site and falls outside the standard building application requirements. Exemption from a formal surveying process does not absolve the developer from ensuring structural integrity and compliance.

In addition to designing for mechanical forces, buildings must also be structured to withstand fire loads. This includes ensuring that all structural elements, down to the foundations, maintain integrity during a fire.

The S-Base foundation system has undergone full testing by KIWA, and work on a Technical Approval (TG) from SINTEF is in the final phase. Certification is expected to be completed by spring 2025, ensuring that S-Base can be used in building applications and contract agreements.

S-Base can be installed in positions A, B, C, and D, supporting:

Unlike traditional wooden foundations, S-Base does not burn. It is therefore a viable foundation for buildings, provided that the cavity beneath the structure is classified as a ventilated cavity.

Construction: 4.7 tons CO₂

End of life: The foundations are usually sent to a landfill or burned after use, releasing an additional 7.7 tons CO₂

Total for 15 buildings: 186 tons CO₂

Expected lifespan: For one project only

Construction: 11.4 tons CO₂

End of life: Must be demolished and disposed of as hazardous waste

Total for 15 buildings: 171 tons CO₂

Expected lifespan: For one project only

Construction: 0.7 tons CO₂

End of life: Reused, cleaned, and maintained in a circular system

Total for 15 buildings: 11 tons CO₂

Expected lifespan: > 80 years

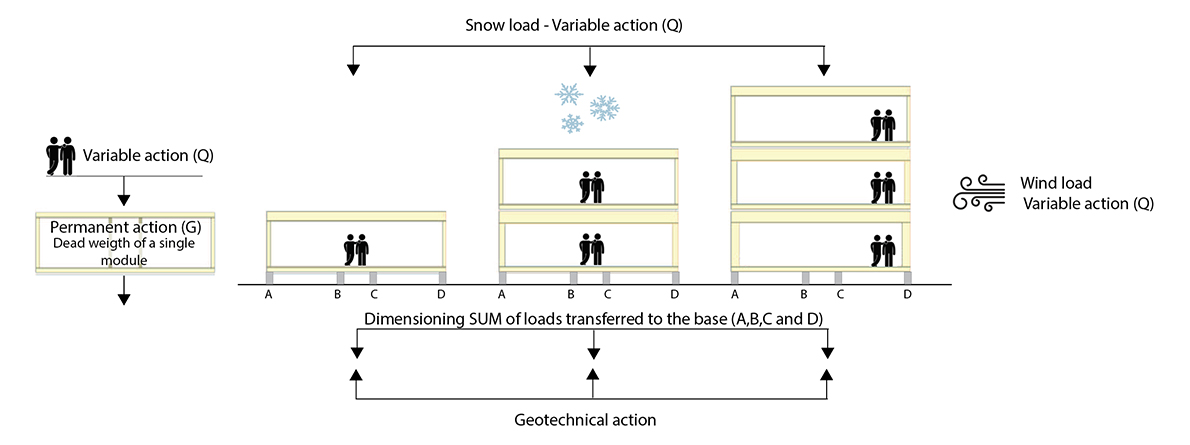

The following diagram illustrates the forces that must be considered in a typical construction project, including temporary buildings:

Regulatory Compliance: Authorities require these calculations to be conducted, even for temporary buildings that do not require a formal building application. Developers must ensure structural integrity regardless.

Beyond mechanical force design, fire safety is a critical factor. The entire structure, including the foundation, must withstand all applied loads even in case of a fire.

S-Base has undergone full testing by KIWA and is in the final phase of obtaining Technical Approval (TG) from SINTEF, expected in spring 2025.

Once certified, S-Base can be used in building applications and contractual agreements.

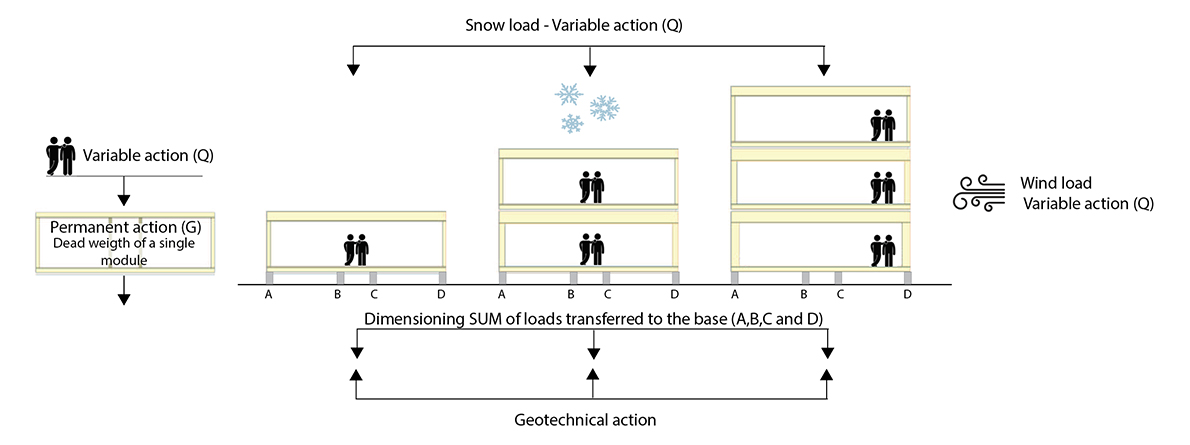

S-Base, through its construction, functions as a 100% effective capillary breaking layer between moist soil and the wooden structure in a building module. By using S-Base, this construction is in line with the requirements of all different module manufacturers who hold a Technical Approval from SINTEF.

Over the years, we have found that fungus is occasionally discovered inside modules that have been in use for a few years. Living in buildings with moisture and mold damage increases the risk of health problems. Research shows that respiratory diseases are more prevalent among those who live or stay in buildings with poor indoor climates – especially where there is mold and moisture...

Masonry and concrete are also susceptible to capillary suction.

This type of dampness usually affects the width of the wall with a height of between 50 and 120 cm and occurs throughout the year...

The following description of S-Base is based on terms defined in the EUROCODE, a set of European standards for the design of structures. These standards ensure the safety and durability of buildings and civil engineering works, considering geotechnical aspects, structural fire design, earthquake resistance, and temporary structures.

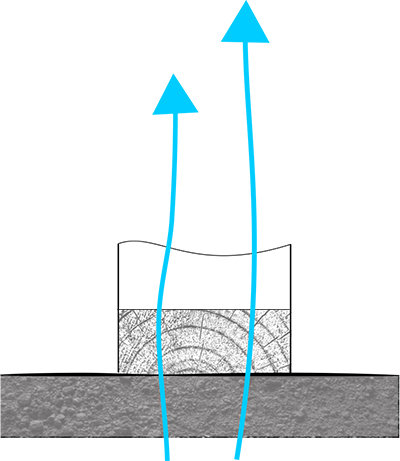

S-Base is defined as a foundation pile, which is considered a load-bearing member, a structural member, and a physically distinguishable part of the overall structural system, describing how these members work together to provide support.

S-Base is designed for a working life of up to 80 years, with appropriate maintenance. While temporary structures are assumed to have a working life of 10 years, S-Base is classified as a long-term solution, not temporary.

The design of S-Base takes into account load arrangements, including force direction, magnitude, and position. The load cases, deformations, and imperfections are considered alongside permanent, variable, and fixed actions to meet EUROCODE requirements.

S-Base has the necessary bending, buckling, and tension resistance to handle mechanical forces without failure. Standard components are selected to meet these high criteria.

Strength tests conducted by KIWA confirm that the galvanized and powder-coated steel parts are durable enough for their purpose. The results include:

S-Base is designed to withstand the following structural actions:

In accordance with EUROCODE, S-Base meets the required fire resistance standards:

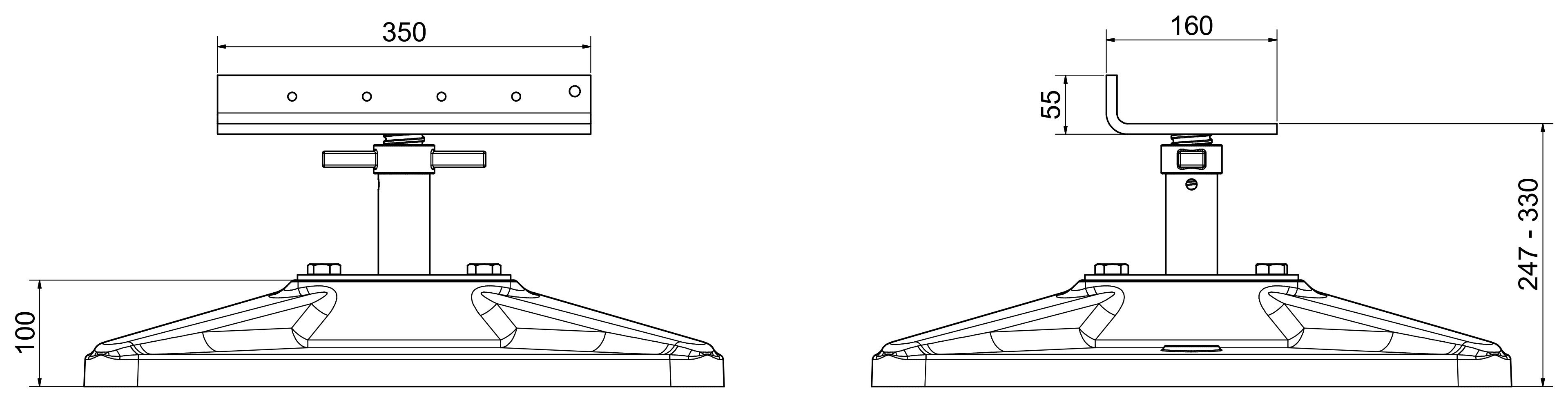

The drawing below shows the basic model of S-Base (S1S-Base-A-2). Extensions allow height adjustments from 330 mm to 700 mm.

Specifications and Compliance

S-Base™ meets EUROCODE standards and is designed for permanent, variable, and geotechnical actions.

Estimated at 80 years, based on environmental conditions and protective coatings.

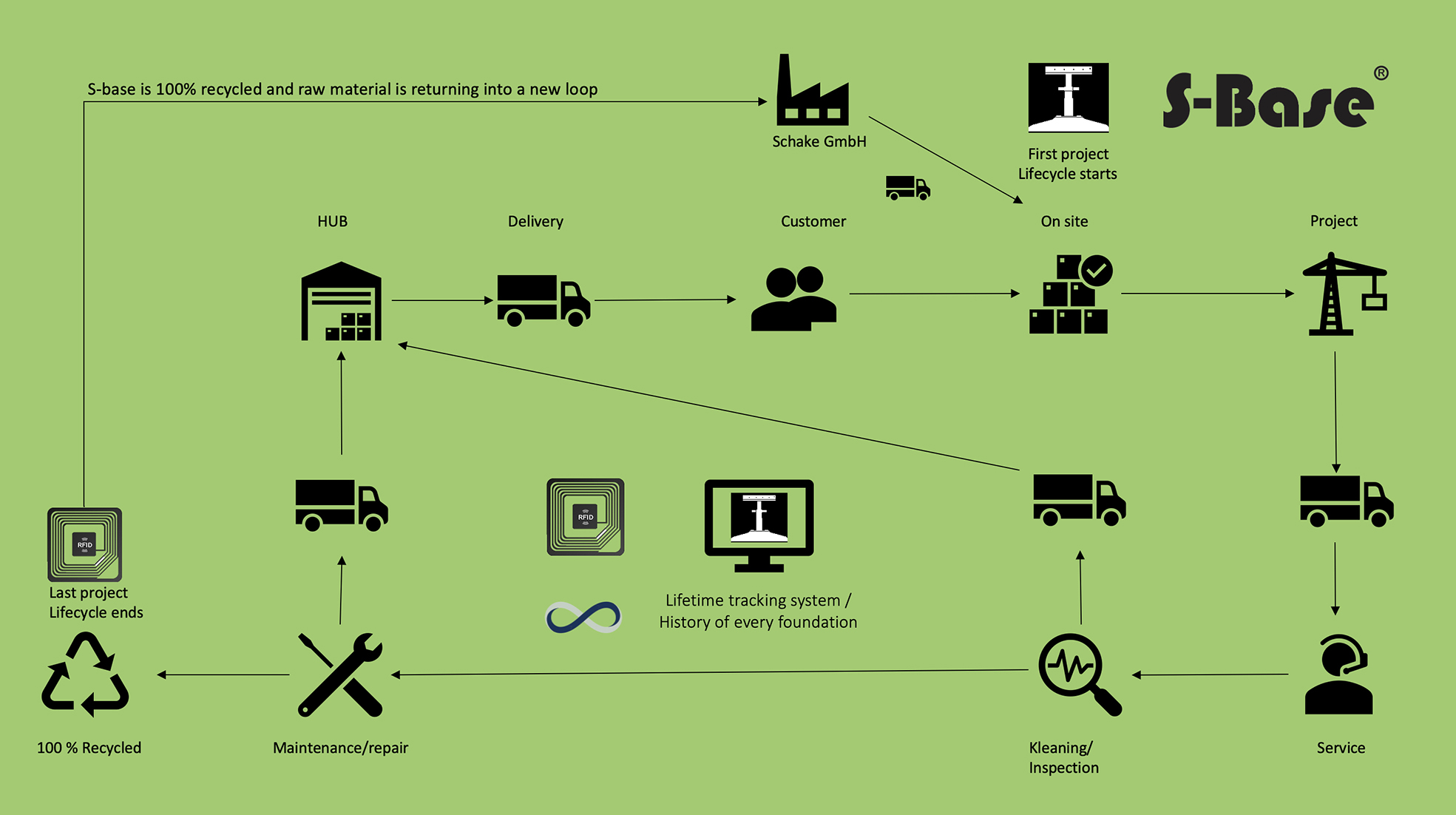

The S-Base™ is a foundation system developed by Solidum EST in Norway and manufactured under license by Schake GmbH in Germany. The product is marketed in the EU and Nordic countries, with a business model based on rental or subscription solutions.

All components are equipped with unique serial numbers, ensuring full traceability. Each foundation is fitted with QR codes and RFID technology, linked to the quality system, providing a comprehensive overview of where the foundations are used and their entire lifecycle history.

No substance present in the product with a concentration exceeding 0.1% of the total weight is included on the "List of Substances of Very High Concern (SVHC)" for authorization under REACH legislation.

The production process for S-Base™ involves a series of high-quality manufacturing steps. Individual components such as steel, 360 PVC soft, welding consumables, coating materials, and other ancillary materials are delivered to the production facility.

Until used in production, raw materials are stored in a warehouse. The processes performed at the facility include:

The manufacturing process starts with German steel (3-10 mm thick) and recycled PVC base plates (360 PVC soft). Steel sheets and tubes are precision cut using CNC-controlled lasers to optimize resource efficiency.

Before coating, the steel undergoes multiple cleaning steps to enhance adhesion. The components are then hot dip galvanized at 450°C using renewable energy and finished with a green powder coating that meets C5 corrosion standards.

The 360 PVC soft base plates are made from recycled materials. Final assembly utilizes stainless or acid-resistant fasteners, and each foundation is scanned via RFID for quality control before packaging.

The total Global Warming Potential (GWP) for S-Base™ is calculated at 3.87 kg CO₂ equivalent, demonstrating a commitment to environmental responsibility.

Environmental Product Declaration (EPD) According to ISO 14025 and EN 15804Discover how S-Base™ has been implemented in various projects.

The system has been developed by Solidum EST in Norway and is manufactured under license by Schake GmbH in Germany.

Our business model is based on rental or subscription solutions, often referred to as circular or 360° solutions. For longer-term projects (over 36 months), foundations may also be sold with a “buy back” option when the project is demobilized. This approach ensures recycling is an integral part of the solution.

Each foundation is equipped with unique serial numbers for 100% traceability. For rental solutions, foundations are equipped with QR codes and RFID technology, linked to our quality system for full oversight on usage and lifecycle history.

Innovative Foundation Solutions for Temporary Buildings

Owner: Solidum EST AS

Organisation No: NO 928 784 835 MVA

E-mail: post@s-base.no

Website: www.s-base.no

Address:

Solidum EST AS,

Stjørdølaveien 17 C,

5515 Haugesund, Norway